簡介

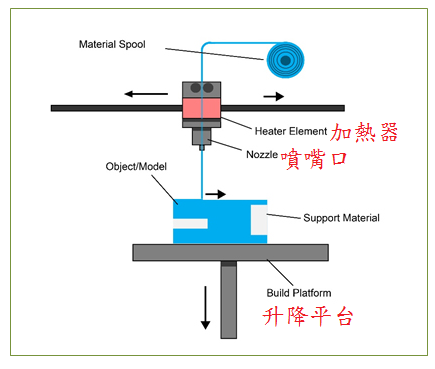

材料先被捲成管狀或絲線狀,然後被餵入加熱器(heater)中受熱,在噴嘴口(nozzle)處熔融擠出,擠出後呈現半流體狀(類似牙膏),並一層一層的沉積在升降平台(platform)上。

製造過程分為以下幾個步驟 :

- 在升降平台(platform)的橫截面上,第一層經由噴嘴口(nozzle)被加熱擠出。

- 第二層經由噴嘴口被加熱擠出,堆疊沉積在第一層上。

- 第三層、第四層…依此類推 (後層堆疊在前層上)。

- 重複相同步驟直到物件加工完畢。

比較表格

| Typical | Feasible | |

|---|---|---|

| Shapes: | ||

| Part size: | ||

| Materials: | ||

| Surface finish - Ra: | ||

| Tolerance: | ||

| Max wall thickness: | ||

| Quantity: | ||

| Lead time: | ||

| Advantages: | ||

| Disadvantages: | ||

| Applications: | ||

Disclaimer: All process specifications reflect the approximate range of a process's capabilities and should be viewed only as a guide. Actual capabilities are dependent upon the manufacturer, equipment, material, and part requirements.