製造過程分為以下幾個步驟 :

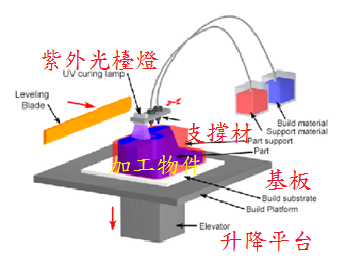

- 使噴頭(print head)位於升降平台上方。

- 藉由 加熱或壓電的方式(thermal or piezoelectric method),材料液滴從噴頭射出,沉積到基板(substrate)表面。

- 材料液滴固化,製造出第一層。

- 依此類推,藉由後層液滴沉積在前層的方式,依次建構出第二層、第三層...。

- 每一層硬化方式包含:自然冷卻硬化或照射紫外光固化。後處理時必須去除支撐材料(support material)。

表格比較

| Typical | Feasible | |

|---|---|---|

| Shapes: | ||

| Part size: | ||

| Materials: | ||

| Surface finish - Ra: | ||

| Tolerance: | ||

| Max wall thickness: | ||

| Quantity: | ||

| Lead time: | ||

| Advantages: | ||

| Disadvantages: | ||

| Applications: | ||

Disclaimer: All process specifications reflect the approximate range of a process's capabilities and should be viewed only as a guide. Actual capabilities are dependent upon the manufacturer, equipment, material, and part requirements.